In automotive maintenance, one question frequently arises: can we use fuel injector cleaner on direct injection engines? With the increasing popularity of direct injection technology, car owners must understand how to maintain these engines properly. In this article, we will explore the compatibility of fuel injector cleaners with direct injection engines and shed light on the best practices for keeping these engines running smoothly.

What is a Direct Injection Engine?

Overview of direct injection engines

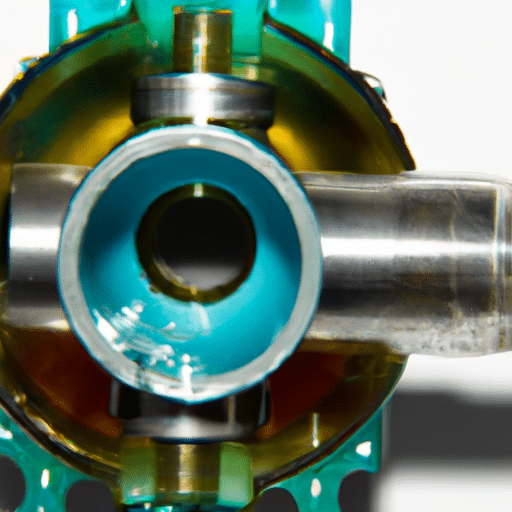

Direct injection engines are a type of internal combustion engine where fuel is directly injected into the combustion chamber rather than injected into the intake manifold. This allows for a more precise and efficient fuel delivery system, improving performance and fuel economy.

In a direct injection engine, the fuel is injected at a higher pressure directly into the combustion chamber, where it mixes with the air for combustion. This direct fuel delivery ensures a more efficient and complete combustion process, resulting in increased power output and reduced fuel consumption.

Key differences compared to traditional fuel injection systems

One of the key differences between direct injection engines and traditional fuel injection systems is the location at which the fuel is injected. In traditional fuel injection systems, the fuel is injected into the intake manifold, allowing it to mix with the incoming air before entering the combustion chamber.

Another difference is the pressure at which fuel is injected. Direct injection engines operate at higher fuel pressures, typically 500 to 2000 psi, compared to traditional fuel injection systems, which operate at lower pressures.

These critical differences in fuel delivery contribute to the improved performance and fuel efficiency of direct injection engines. However, they also require specific maintenance considerations, such as using fuel injector cleaners specifically formulated for direct injection engines.

How Do Fuel Injectors Work?

Function and role of fuel injectors

Fuel injectors play a crucial role in the overall functioning of an engine. Their primary function is to deliver a precise amount of fuel into the combustion chamber at the right time. This is achieved through a series of steps:

- Opening: The fuel injector receives an electrical signal from the engine control unit (ECU) to open, allowing pressurized fuel to flow through.

- Spray pattern: Once opened, the fuel injector atomizes the fuel into a fine mist or spray pattern. This ensures optimal fuel-air mixture for combustion.

- Timing: The fuel injector opens and closes rapidly, which determines the duration and timing of fuel injection. This is crucial for engine performance and efficiency.

Importance of keeping fuel injectors clean

Clean fuel injectors are essential for maintaining the performance and efficiency of an engine. Over time, dirt, carbon deposits, and other contaminants can build up in the fuel injectors, leading to a range of issues:

- Poor fuel atomization: If the fuel injectors are clogged or dirty, they may not be able to properly atomize the fuel, resulting in a less efficient combustion process.

- Reduced fuel efficiency: Clogged fuel injectors can lead to incomplete combustion and fuel wastage, reducing overall fuel efficiency.

- Engine misfires: Buildup in fuel injectors can cause an uneven fuel distribution to the cylinders, leading to engine misfires, rough idle, and decreased performance.

Regular cleaning of fuel injectors, either through professional cleaning or fuel injector cleaners, is crucial to prevent these issues and maintain optimal engine performance.

Understanding Fuel Injector Cleaners

What are fuel injector cleaners?

Fuel injector cleaners are chemical additives specifically formulated to clean and maintain the fuel injectors. They help remove deposits, gunk, and carbon buildup inside the injectors, ensuring proper fuel flow and atomization.

These cleaners contain detergents and solvents that break down and dissolve the deposits, allowing them to be safely burned off during the combustion process. They are typically added to the fuel tank and mixed with the gasoline, where they can effectively clean the fuel injectors as the engine runs.

Types of fuel injector cleaners

There are various types of fuel injector cleaners available on the market. Some are designed for general use and can be used in any engine, while others are specifically formulated for direct injection engines. When selecting a fuel injector cleaner, it is essential to choose one that is compatible with the type of engine and fuel system you have.

It is recommended to consult the owner’s manual or the manufacturer’s guidelines to ensure you select the appropriate fuel injector cleaner for your direct injection engine. Using the right cleaner will ensure effective cleaning without causing any damage to the engine or its components.

Direct Injection Engines and Fuel Injector Cleaners

Compatibility of fuel injector cleaners with direct injection engines

Fuel injector cleaners can be used on direct injection engines, provided the cleaner is specifically formulated and labeled as suitable for such engines. It is essential to choose a cleaner that meets the manufacturer’s specifications for your particular engine.

Direct injection engines have specific fuel system components and require cleaners that can effectively remove carbon buildup and deposits from the fuel injectors without causing harm to the delicate components. Using a cleaner designed for direct injection engines will ensure maximum effectiveness and safety.

Potential risks or concerns

While fuel injector cleaners are generally safe to use on direct injection engines, it is essential to follow the instructions provided by the manufacturer. Some potential risks or concerns to consider include:

- Overuse: Using too much fuel injector cleaner too frequently can potentially damage the fuel injectors or other fuel system components. It is crucial to follow the recommended dosage and frequency guidelines.

- Improper use: If the cleaner is added incorrectly or not appropriately mixed with the fuel, it may not reach the fuel injectors for effective cleaning. It is essential to follow the instructions for use provided by the manufacturer carefully.

- Compatibility issues: Using a fuel injector cleaner not specifically formulated for direct injection engines can potentially cause damage to the fuel system components. Always choose a cleaner that is labeled as compatible with direct injection engines.

To mitigate these risks, it is advisable to consult the owner’s manual, seek advice from a qualified mechanic, or contact the manufacturer for guidance on using fuel injector cleaners on direct injection engines.

Benefits of Using Fuel Injector Cleaners on Direct Injection Engines

Improved fuel efficiency

One of the main benefits of using fuel injector cleaners on direct injection engines is improved fuel efficiency. Over time, fuel injectors can become clogged or dirty, leading to inefficient fuel delivery.

By regularly using a fuel injector cleaner, you can remove deposits and carbon buildup, allowing the fuel injectors to function optimally. This results in better fuel atomization and combustion, improving fuel efficiency and potentially reducing fuel consumption.

Enhanced engine performance

Dirty or clogged fuel injectors can negatively impact engine performance. They can cause rough idle, misfires, decreased power, and sluggish acceleration. Using a fuel injector cleaner on direct injection engines can help restore the fuel injectors’ optimal function, resulting in smoother operation, improved throttle response, and enhanced engine performance.

Preventing or resolving fuel injector issues

Regular use of fuel injector cleaners can help prevent or resolve fuel injector issues in direct injection engines. By keeping the fuel injectors clean and free from deposits, you can minimize the risk of clogging, reduced fuel flow, and uneven fuel distribution.

Preventing these issues can extend the lifespan of the fuel injectors and other fuel system components, ultimately leading to a more reliable and efficient engine.

Choosing the Right Fuel Injector Cleaner

Considerations for selecting a fuel injector cleaner

When selecting a fuel injector cleaner for your direct injection engine, it is essential to consider the following factors:

- Compatibility: Ensure the cleaner is specifically formulated and labeled suitable for direct injection engines. This will ensure maximum effectiveness and compatibility with your engine.

- Manufacturer’s recommendations: Refer to the owner’s manual or contact the manufacturer to understand their recommendations for fuel injector cleaners. They may provide specific guidelines or recommend particular brands or products.

- Reputation and reviews: Research and read reviews about different fuel injector cleaners to determine their effectiveness and reliability. Look for products with positive feedback and high ratings.

Recommended products for direct injection engines

While specific product recommendations may vary depending on your engine and its requirements, some well-regarded fuel injector cleaners are often recommended for direct injection engines. These include:

- BG 44K Fuel System Cleaner: Known for its powerful cleaning properties and ability to remove deposits from fuel injectors and other engine components.

- Chevron Techron Concentrate Plus: A trusted brand frequently recommended for cleaning fuel injectors and improving engine performance.

- Sea Foam SF-16 Motor Treatment: This multipurpose cleaner is known for its ability to clean fuel injectors, remove carbon buildup, and lubricate engine components.

It is important to note that these recommendations are not exhaustive, and it is always best to refer to your owner’s manual or consult a qualified mechanic for specific product recommendations suited to your direct injection engine.

How to Use Fuel Injector Cleaner on Direct Injection Engines

Step-by-step instructions for using fuel injector cleaner

Using a fuel injector cleaner on a direct injection engine is relatively simple. Here are some general step-by-step instructions to guide you:

- Read the instructions: Carefully read and understand the instructions provided by the manufacturer of the fuel injector cleaner you are using.

- Determine the appropriate dosage: Refer to the instructions or consult the product labeling to determine the correct amount of cleaner to use. This is usually based on the capacity of your fuel tank.

- Add the cleaner to the fuel tank: Pour the recommended amount of fuel injector cleaner into the tank before filling it with gasoline. This ensures proper mixing and distribution of the cleaner throughout the fuel system.

- Fill up the tank: After adding the cleaner, fill up the fuel tank with gasoline as you usually would. This will help dilute the cleaner and aid its dispersion through the fuel system.

- Drive usually: Drive your vehicle as you normally would to allow the fuel injector cleaner to circulate through the system and clean the fuel injectors. It is recommended to use the cleaner over a few tankfuls of fuel to ensure thorough cleaning.

Always follow the specific instructions provided by the manufacturer of the fuel injector cleaner you are using, as different products may have slightly different usage guidelines.

Frequency and maintenance tips

The frequency of using a fuel injector cleaner on a direct injection engine can vary depending on several factors, including the fuel being used, driving conditions, and the overall condition of the fuel injectors.

As a general guideline, it is recommended to use a fuel injector cleaner every 3,000 to 5,000 miles or every three to six months. However, it is best to consult the owner’s manual or the manufacturer’s recommendations for a more specific interval suited to your engine.

In addition to using fuel injector cleaners, there are other maintenance tips to keep in mind for optimal performance of your direct injection engine:

- Use high-quality fuel: High-quality fuel with the recommended octane rating can help prevent deposits and carbon buildup in the fuel injectors.

- Regularly replace filters: Regularly replacing the fuel and air filters can help prevent contaminants from entering the fuel injectors and ensure a clean air-fuel mixture.

- Avoid prolonged idling: Extended periods can cause fuel residue to build up in the fuel injectors. Minimizing idle time can help prevent this buildup.

- Regular engine tune-ups: Following the recommended maintenance schedule for your vehicle, including spark plug replacement and ignition system checks, can help maintain optimal engine performance.

By following these maintenance tips and incorporating regular use of fuel injector cleaners, you can keep your direct injection engine running smoothly and efficiently.

Professional Cleaning vs. Fuel Injector Cleaners

Comparison between professional cleaning and fuel injector cleaners

Professional cleaning and fuel injector cleaners are two options for maintaining the cleanliness of fuel injectors in a direct injection engine. Here are some key points of comparison:

- Cost: Fuel injector cleaners are generally more cost-effective than professional cleaning services. The cleaners can be purchased at a relatively low price and used without requiring specialized tools or equipment.

- Convenience: Using a fuel injector cleaner at home is convenient and easily incorporated into regular maintenance routines. Professional cleaning, on the other hand, may require a visit to an automotive service center, scheduling an appointment, and possibly leaving your vehicle for some time.

- Effectiveness: While both options can effectively clean fuel injectors, professional cleaning may provide a more thorough cleaning. Professionals have specialized equipment and knowledge to perform deep cleaning procedures that are impossible with fuel injector cleaners alone.

When to seek professional cleaning

While using fuel injector cleaners can effectively clean fuel injectors in most cases, there may be instances where professional cleaning is recommended or necessary. These include:

- Severe deposits: If the fuel injectors are heavily clogged with deposits or carbon buildup, professional cleaning may be required for a more thorough cleaning.

- Persistent issues: If you continue to experience fuel delivery problems, rough idle, misfires, or decreased performance even after using fuel injector cleaners, it may be a sign of more severe issues. In such cases, seeking professional cleaning can help diagnose and resolve the underlying problems.

- Manufacturer’s recommendations: Some vehicle manufacturers may recommend professional cleaning at specific mileage intervals as part of their maintenance schedule. It is essential to follow these recommendations to ensure optimal performance and longevity of the engine.

When considering professional cleaning, it is advisable to consult a qualified mechanic or contact the automobile manufacturer for recommendations and guidance specific to your vehicle and engine.

Common Misconceptions about Fuel Injector Cleaners and Direct Injection Engines

Dispelling myths and misconceptions

There are several myths and misconceptions surrounding the use of fuel injector cleaners on direct injection engines. Let’s address and dispel some of the common ones:

- Myth: Fuel injector cleaners can harm the engine.

Fact: When used correctly and according to the manufacturer’s instructions, fuel injector cleaners are designed to be safe for the engine. It is essential to choose a cleaner compatible with direct injection engines and use the recommended dosage.

- Myth: Fuel injector cleaners can fix all engine-related problems.

Fact: While fuel injector cleaners can help resolve fuel injector issues and improve performance, they may not fix all engine-related problems. There can be underlying issues that require professional diagnosis and repair.

- Myth: Using more fuel injector cleaners will provide better results.

Fact: It is essential to use the recommended dosage of fuel injector cleaner, as using more than necessary can potentially harm the engine. Follow the instructions provided by the manufacturer for optimal results.

- Myth: Fuel injector cleaners are only for old or high-mileage engines.

Fact: Fuel injector cleaners benefit both older and newer engines, as they help prevent and resolve fuel injector issues. Regular use can help maintain optimal performance in all engines, regardless of mileage.

By dispelling these misconceptions, it becomes clear that fuel injector cleaners are a valuable tool for maintaining and optimizing the performance of direct injection engines.

Essential Maintenance for Direct Injection Engines

Other maintenance tasks for optimal engine performance

In addition to using fuel injector cleaners, there are other essential maintenance tasks to keep direct injection engines in optimal condition. These tasks include:

- Regular oil changes: Regularly changing the engine oil and oil filter is crucial for lubrication and performance. Follow the recommended intervals provided by the manufacturer.

- Coolant system maintenance: Ensure the coolant system is maintained correctly by regularly checking coolant levels, inspecting hoses for leaks or wear, and flushing the system as recommended.

- Ignition system maintenance: Check and replace spark plugs, ignition coils, and other components per the manufacturer’s recommendations.

- Air filter replacement: Regularly replace the air filter to ensure proper airflow and prevent contaminants from entering the engine.

Maintaining cleanliness of other engine components

While fuel injector cleanliness is crucial, it is also essential to maintain the cleanliness of other engine components. Perform these tasks to keep your direct injection engine running smoothly:

- Carbon buildup prevention: Carbon buildup can occur on intake valves in direct injection engines. Consider using intake valve cleaners specifically formulated for direct injection engines to prevent carbon buildup and ensure optimal performance.

- Throttle body cleaning: Cleaning the throttle body periodically helps maintain smooth airflow and prevent idle issues. Consult the owner’s manual or a qualified mechanic for instructions on proper cleaning techniques.

- Intake system inspection: Regularly inspect the intake system for any signs of dirt or debris and clean as necessary. This will help maintain proper airflow and prevent contaminants from entering the combustion chamber.

By incorporating these maintenance tasks into your routine, you can ensure the longevity, performance, and efficiency of your direct injection engine.

In conclusion, fuel injector cleaners can be safely and effectively used on direct injection engines to maintain optimal fuel delivery and performance. They help improve fuel efficiency, enhance engine performance, and prevent or resolve fuel injector issues. By selecting the right fuel injector cleaner, following proper usage instructions, and incorporating regular maintenance, you can keep your direct injection engine running smoothly for years.