Have you ever wondered why diesel fuel sometimes turns into an unpleasant, gel-like substance? We’re here to shed some light on this perplexing phenomenon. When temperatures drop below freezing, diesel fuel can undergo a process called “fuel gelling.” This occurs when the paraffin wax, present in diesel fuel, starts to solidify and form clusters, obstructing fuel filters and causing the engine to lose power. Stay tuned as we explore the factors contributing to this irritating issue and how to prevent it from happening to your vehicle.

Factors Affecting Diesel Fuel Gelling

Low Temperature

Low temperature is one of the primary factors that can lead to diesel fuel gelling. When the temperature drops, the paraffin wax present in the fuel can solidify, causing it to thicken and turn into a gel-like consistency. This can significantly impact diesel engines’ performance, leading to issues such as clogged fuel filters and engine stalling.

Paraffin Wax Content

The paraffin wax content in diesel fuel is crucial in its susceptibility to gelling. Diesel fuels with high paraffin wax content are more prone to gelling at low temperatures. When exposed to cold temperatures, Paraffin wax, present naturally in crude oil, can crystallize and form solid masses. These solid masses can obstruct the fuel filters and restrict the fuel flow, resulting in engine problems.

Fuel Additives

Fuel additives are chemical compounds mixed with diesel fuel to enhance their performance and prevent various issues, including fuel gelling. Certain additives, commonly known as anti-gel agents, can modify the characteristics of diesel fuel at low temperatures, preventing the formation of solid wax crystals. These additives help maintain the fuel’s fluidity and ensure smooth engine operation even in cold weather conditions.

Contaminants

Contaminants present in diesel fuel can exacerbate the problem of fuel gelling. Water, which can enter the fuel system through condensation or storage practices, can accelerate the formation of solid wax crystals and promote fuel gelling. Moreover, microbial growth in diesel fuel tanks can release byproducts that contribute to forming gel-like substances. Additionally, sediments and particulate matter present in the fuel can act as nucleation sites for wax crystallization, further increasing the chances of fuel gelling.

Effects of Diesel Fuel Gelling

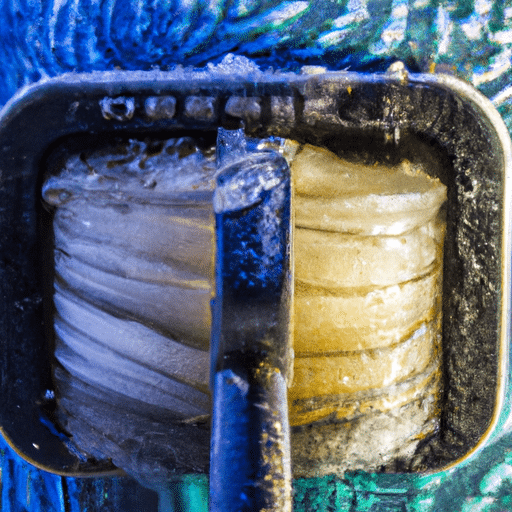

Clogged Fuel Filters

One of the most noticeable effects of diesel fuel gelling is the clogging of fuel filters. As the fuel thickens and forms gel-like substances, it can easily obstruct the fuel filters, leading to restricted fuel flow. Clogged fuel filters can cause various issues, including reduced engine performance, increased fuel consumption, and engine failure if left untreated. Regular inspection and replacement of fuel filters are necessary to prevent these problems.

Reduced Fuel Flow

Diesel fuel gelling can significantly reduce the fuel flow to the engine. As the fuel thickens, passing through the fuel lines and reaching the engine efficiently becomes difficult. This reduced fuel flow can decrease engine power, sluggish acceleration, and poor performance. It is crucial to promptly address the issue of fuel gelling to ensure smooth fuel flow and optimal engine operation.

Engine Stalling

If left untreated, diesel fuel gelling can lead to engine stalling. As the fuel thickens and obstructs the fuel filters and lines, the engine may not receive an adequate fuel supply. This can cause the engine to stall abruptly, leaving the vehicle or equipment inoperable. Engine stalling can be dangerous, mainly in critical situations such as busy highways or remote areas. Therefore, preventative measures are vital to avoid such incidents.

Prevention and Treatment of Diesel Fuel Gelling

Winter-blend Diesel Fuel

One effective method to prevent diesel fuel gelling is winter-blend diesel fuel. Winter-blend diesel fuels are specifically formulated to resist gelling in cold temperatures. These fuels typically contain a higher concentration of lighter hydrocarbons and have lower paraffin wax content, making them less susceptible to gelling. Switching to winter-blend diesel fuel before the onset of cold weather can significantly reduce the risk of fuel gelling.

Fuel Additives and Anti-Gel Agents

Fuel additives and anti-gel agents are other practical solutions for preventing and treating diesel fuel gelling. These additives are designed to modify the fuel’s properties at low temperatures, inhibiting the formation of solid wax crystals. Adding anti-gel agents to the fuel enhances the fuel’s cold flow properties, ensuring smooth fuel flow even in freezing conditions. Regular fuel additives can provide an added layer of protection against fuel gelling.

Fuel Filter Heaters

Fuel filter heaters are devices installed in the fuel system to counteract the effects of diesel fuel gelling. These heaters are designed to heat the fuel before it reaches the fuel filters, preventing the formation of solid wax crystals and ensuring uninterrupted fuel flow. Fuel filter heaters are particularly beneficial in frigid climates or for vehicles and equipment that operate in sub-zero temperatures. However, it is essential to note that fuel filter heaters have limitations and should be used with other preventive measures.

Low Temperature

Impact on Diesel Fuel Gelling

Low temperatures have a significant impact on the occurrence of diesel fuel gelling. When the ambient temperature drops, the paraffin wax present in the fuel starts to solidify, leading to the formation of gel-like substances. The colder the temperature, the higher the chances of fuel gelling. Understanding the relationship between temperature and fuel gelling is essential to prevent and manage this issue effectively.

Operability of Diesel Engines

Low temperature and diesel fuel gelling can severely affect the operability of diesel engines. When the fuel thickens and forms gels, it becomes increasingly difficult for the fuel to flow through the fuel system and reach the engine. This restricts the fuel supply, leading to reduced engine performance, increased fuel consumption, and potential engine stalling. It is crucial to take appropriate preventive measures to ensure that diesel engines remain operational even in frigid conditions.

Paraffin Wax Content

Paraffin Wax Formation

Paraffin wax is a natural component in crude oil and diesel fuels. When the fuel is exposed to low temperatures, the paraffin wax can solidify and form crystals. These crystallized wax particles can then aggregate, leading to the formation of gel-like substances. The paraffin wax content in diesel fuel plays a significant role in the likelihood of fuel gelling, with higher paraffin wax content increasing the susceptibility to gelling.

Effects on Fuel Flow

The presence of paraffin wax in diesel fuel can have a detrimental effect on fuel flow. As the wax particles start to solidify and aggregate, they can obstruct the fuel filters and lines, restricting fuel flow to the engine. This reduced fuel flow can cause engine issues such as reduced power, decreased acceleration, and poor overall performance. It is essential to address the paraffin wax content in diesel fuel to ensure smooth fuel flow and prevent fuel gelling.

Cloud Point and Cold Filter Plugging Point

The cloud point and cold filter plugging point are two crucial parameters that indicate the low-temperature performance of diesel fuel. The cloud point refers to the temperature at which paraffin wax crystals form and become visible in the fuel. On the other hand, the cold filter plugging point is the temperature at which the fuel becomes too dense and starts to clog the fuel filters. Monitoring these parameters can help determine the suitability of diesel fuel for cold weather conditions and take appropriate preventive measures.

Viscosity

The viscosity of diesel fuel also plays a role in its susceptibility to gelling. As the temperature drops, the viscosity of the fuel increases, making it thicker and less fluid. This increased viscosity can hinder the fuel’s ability to flow through the fuel system, leading to reduced fuel flow and potential fuel gelling. Managing the viscosity of diesel fuel is crucial to prevent issues related to gelling and maintain optimal engine performance in cold weather conditions.

Fuel Additives

Purpose and Types of Fuel Additives

Fuel additives are chemical compounds added to diesel fuel to improve performance and address various issues. Regarding fuel gelling, certain additives known as anti-gel agents are particularly effective. These additives help modify the characteristics of diesel fuel at low temperatures, inhibiting the formation of solid wax crystals and preventing fuel gelling. Different fuel additives may offer specific benefits, such as improving fuel stability, reducing emissions, or enhancing lubricity.

Effects on Fuel Gelling

Fuel additives, specifically anti-gel agents, have a direct impact on preventing fuel gelling. By modifying the fuel’s properties at low temperatures, these additives disrupt the formation of solid wax crystals and enhance the fuel’s cold flow properties. This ensures the fuel remains fluid and can flow smoothly through the system, preventing clogging and fuel filter blockages. Regular use of fuel additives can significantly reduce the risk of fuel gelling and maintain optimal engine performance in cold weather conditions.

Contaminants

Water

Water is a common contaminant found in diesel fuel and can contribute to the problem of fuel gelling. When water enters the fuel system, it can accelerate the formation of solid wax crystals by providing a medium for nucleation. Water can also foster the growth of microbial organisms, which can release byproducts that promote fuel gelling. Proper fuel storage practices, such as keeping fuel tanks tightly sealed and using water separation filters, can help minimize water contamination and prevent fuel gelling.

Microbial Growth

Microbial growth in diesel fuel tanks can significantly impact fuel gelling. Microbes, such as bacteria and fungi, can thrive in water-contaminated fuel tanks and release byproducts that contribute to forming gel-like substances. These byproducts can act as nucleation sites for wax crystallization, exacerbating the problem of fuel gelling. Regular fuel tank inspections, fuel treatments, and implementing proper fuel storage practices are essential to prevent microbial growth and reduce fuel gelling risk.

Sediments and Particulate Matter

Sediments and particulate matter in diesel fuel can also contribute to the development of fuel gelling. These contaminants can act as nucleation sites for forming solid wax crystals. When the fuel is exposed to low temperatures, the wax crystals can aggregate around these contaminants, forming gel-like substances. Proper filtration and regular fuel system maintenance, including fuel filter replacement, are necessary to prevent the accumulation of sediments and particulate matter and minimize the risk of fuel gelling.

Clogged Fuel Filters

Mechanism of Fuel Filter Clogging

Fuel filter clogging is a common consequence of diesel fuel gelling. As the fuel thickens and forms gel-like substances, it can easily obstruct the filters. These gel-like substances can accumulate in the fuel filters, reducing efficiency and restricting fuel flow. Clogged fuel filters can lead to reduced engine performance, increased fuel consumption, and potential engine stalling. Regular monitoring and replacement of fuel filters are essential to prevent fuel filter clogging and maintain optimal engine operation.

Fuel Filter Replacement

Regular fuel filter replacement is necessary to mitigate the effects of fuel gelling and prevent fuel filter clogging. Fuel filters should be inspected and replaced according to the manufacturer’s recommendations or when signs of clogging are noticed. When replacing fuel filters, selecting filters suitable for the operating conditions, including the expected temperature range, is essential. Choosing filters designed to resist fuel gelling can help ensure uninterrupted fuel flow and prevent engine issues related to fuel filter clogging.

Reduced Fuel Flow

Effect on Engine Performance

Reduced fuel flow, often caused by diesel fuel gelling, can significantly impact engine performance. When the fuel thickens and obstructs the fuel filters and lines, the engine may not receive an adequate fuel supply. This can result in decreased engine power, poor acceleration, and reduced performance. Sufficient fuel can lead to incomplete combustion, increased emissions, and potentially harmful engine deposits. It is crucial to promptly address the issue of reduced fuel flow to maintain optimal engine performance.

Fuel Line Inspection and Maintenance

Regular inspection and maintenance of fuel lines are essential to ensure proper fuel flow and prevent issues related to reduced fuel flow. Fuel lines should be inspected for any signs of blockages, leaks, or damage. Any obstructions, such as solid wax crystals or contaminants, should be removed to restore smooth fuel flow. Also, proper fuel system maintenance, including fuel additives and anti-gel agents, can help prevent the formation of gel-like substances and ensure uninterrupted fuel flow even in cold weather conditions.

Fuel Filter Heaters

Installation and Function

Fuel filter heaters can be installed in the fuel system to combat the effects of diesel fuel gelling. These heaters typically attach to the fuel filters and use electric heating elements to warm the fuel before it reaches the filters. By heating the fuel, the fuel filter heaters prevent the formation of solid wax crystals and ensure continuous fuel flow. Fuel filter heaters are available in various designs and can be installed in aftermarket and OEM applications.

Benefits and Limitations

Fuel filter heaters offer several benefits in preventing fuel gelling and maintaining optimal engine performance in cold weather. These devices effectively warm the fuel, ensuring smooth flow even in freezing temperatures. By preventing fuel filter clogging, fuel filter heaters reduce the risk of engine stalling and extend the lifespan of fuel filters. However, it is essential to note that fuel filter heaters have limitations. They may not be effective in icy conditions or if the fuel has a very high wax content. Fuel filter heaters require proper installation and regular maintenance to ensure efficient operation.

In conclusion, several factors can affect diesel fuel gelling, including low temperature, paraffin wax content, fuel additives, and contaminants. Diesel fuel gelling can lead to issues such as clogged fuel filters, reduced fuel flow, and engine stalling. Preventive measures such as using winter-blend diesel fuel, fuel additives, and fuel filter heaters can help mitigate the effects of fuel gelling. Regular fuel filter replacement and fuel line maintenance are also crucial to ensure smooth fuel flow and optimal engine performance. By understanding these factors and taking appropriate preventive and treatment measures, diesel fuel gelling can be effectively managed, allowing for reliable operation of diesel engines even in cold weather conditions.